Full Inspection

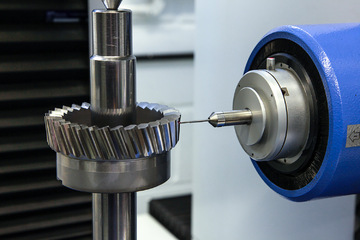

Dathan offer a full inspection and reporting service for gear cutting tools, which can be used in a number of highly effective ways. Our team complete a full inspection of each new tool manufactured before it is dispatched to ensure every one precisely matches your requirements. They can also undertake fault finding inspections to identify problems with gear cutting tools that may be causing issues in your production process.

These can be carried out either by examining photographs or arranging a visit to your site. Inspections can form an important part of the reverse engineering process; for example, if you wish to have a tool made but do not have access to the precise specifications. All inspections include a full report.